Cost-Effective & Fuel-Efficient Technologies

Two of the solutions for post-combustion control systems are Selective Non-Catalytic Reduction (SNCR) and Selective Catalytic Reduction (SCR). Both are of the most cost-effective and fuel-efficient technologies used to reduce stationary source emissions.

Utilizing our field experience and injection technology, LDX Solutions offer complete SCR and SNCR NOx control systems for various plants. State-of-the-art design, simulation, and technology ensure advantages with results that will surpass your requirements and meet guarantees.

Basics Nitrogen Oxides – NOx

NOx is the general term used for NO and NO2, or nitrogen oxides. Three primary sources of NOx: thermal NOx, fuel NOx, and prompt NOx are produced during combustion, especially at high temperatures. In applications such as boiler and kiln, high peak flame temperatures caused by rapid fuel-air mixing in excess available oxygen promote the formation of NOx emissions.

A significant form of air pollution, called photochemical smog, as well as tropospheric ozone, is formed when NOx and volatile organic compounds (VOCs) react in the presence of sunlight.

LDX Solutions Scope for DeNOx Systems

Our team of project engineers and designers work closely with your engineering team to ensure that all specifications and requirements of the SCR or SNCR are seamlessly integrated to the system. Our NOx control systems can be supplied as turnkey solutions including pump & control skids, injection lances & atomization nozzles, control equipment & PLC, catalyst (SCR only), NH3 storage tank, and truck unloading station.

Nitrogen Oxides (NOx) Removal

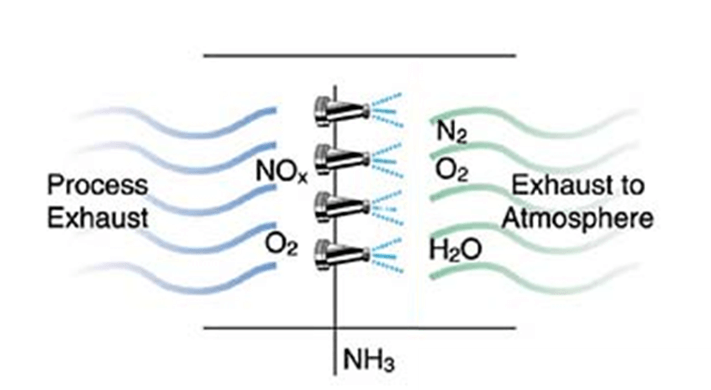

EPA regulations support or require NOx control installations to achieve the lowest emissions level possible. One of the solutions for post-combustion control systems is Selective Non-Catalytic Reduction (SNCR). With this technology, NOx is reduced to nitrogen (N2) and water (H2O) through a series of reactions with a reagent (or reagents) injected into the flue gas. The most common reagents used in commercial applications are ammonia and urea.

The stoichiometric reaction using ammonia for a selective reduction process is:

4NO + 4NH3 + O2 → 4N2 + 6H2O

2NO2 + 4NH3 + O2 → 3N2 + 6H2O

NO + NO2 + 2NH3 → 2N2 + 3H2O

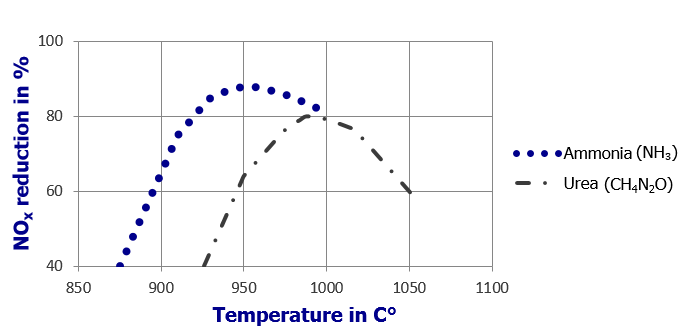

SNCR Process

The optimal temperature range for the SNCR injection of ammonia hydroxide is 900℃-1000°C (1650°F-1830°F) and for urea it is 950°C – 1050°C (1740°F-1920°F).

In addition to the temperature and other factors, the correct ammonia distribution is of importance for ensuring that the process occurs under optimal conditions: The injected droplets must be of optimal size, large enough to provide sufficient impulse and penetration into the flue gas to achieve homogeneous coverage and small enough to reliably evaporate in the required zone. Our injection system effectively meets these requirements and can handle wide fluctuations of NOx concentration in the flue gas.

Utilizing our field experience and injection technology, LDX Solutions offers complete SNCR NOx control systems for various plants. State-of-the-art design, simulation and technology ensure advantages with results that will surpass your requirements and will meet guarantees.

SNCR Testing

LDX Solutions has the capability to provide NOx testing via our portable ammonia injection system and stack testing via our CEMS (continuous emissions monitoring system) trailer.

LDX Product & Solutions for NOx Control

Find out how LDX Solutions can Optimize your Industry

Further making us the best solution for your NOx Control needs is our unparalleled service & life-cycle support. See how our Aftermarket team can keep you online & make you more profitable, regardless of the equipment you currently use.