LDX Solutions Has The Industry Experience

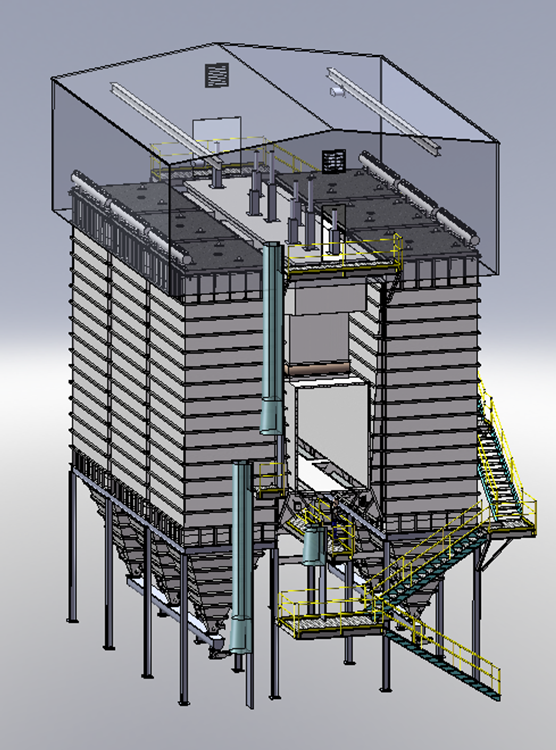

We utilize CFD analysis and 3D CAD systems, developing the optimum custom design for every customer – making us the best choice for your high dust loading or low bulk density material applications.

The primary focuses of our design processes are:

- Best arrangement and access facilities for easy and safe maintenance and minimize footprint.

- Minimization of pressure drop, compressed air consumption, and bag wear to provide lower overall operating costs

- Robust units that come in a modular form to minimize field time and erection expense

Some of the Key design features that set Dustex® systems apart from the competition are:

- Patented Monolithic floating pan top door

- Proprietary, advanced high side entry design

- 4-Wall Modular Design

- Patented Spilt Module design for large volume applications

Basics Particular Matter (PM)

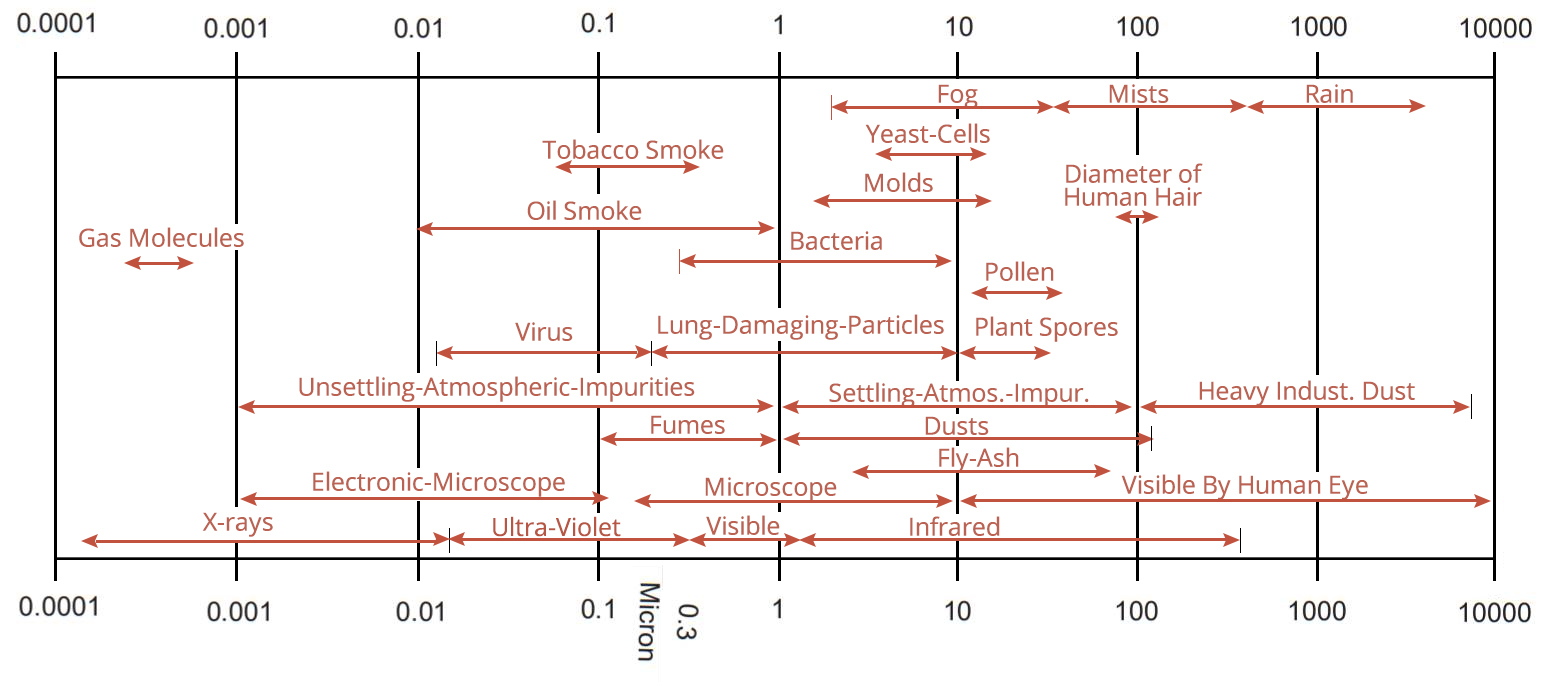

Particulate matter (PM) is the general term used for solid particles and liquid droplets suspended in the ambient air or process gas streams. PM can also be referred to as PM10 and PM2.5 which refer to the aerodynamic equivalent diameter of 10 microns or less and 2.5 microns or less, respectively.

The origin of particulate matter in the ambient air can be natural such as wind-blown dust and volcanoes or human activity such as fossil fuel combustion and automobiles. Particulate matter in the air may also originate from atmospheric reactions between airborne gases such as sulfur oxides, organic compounds and nitrogen oxides.

Most Harmful Form of Air Pollution

Particulate matter is also the leading cause of visibility haze seen in ambient air as well as a nuisance that can soil any surface exposed.

Because of its harmful effects the United States Environmental Protection Agency (US EPA) has made the control of PM a priority. With the passage of the Clean Air Act in 1970 the EPA designated PM as a primary pollutant and has focused much of its enforcement activities on ambient air PM reduction.

What is a baghouse?

A fabric filter dust collector, commonly referred to as a baghouse or just dust collector, is a collection device designed for high removal rates of particles greater than 1 micron. They are utilized in a variety of process applications that generate dust through both mechanical processing and combustion processes in non-saturated gas streams.

Baghouses work by utilizing a permeable barrier through which the process gas passes, allowing the removal of the particulates from the gas stream. Since the gas must pass through this barrier, they are extremely efficient and can achieve removal rates greater than 99.9%. They are designed with integral cleaning systems to remove the collected dust from the filters to allow for continuous operation & increase the filter life. They are commonly used on processes up to 500°F (260°C)

DUSTEX® PULSE-JET FABRIC FILTER

The pulse-jet type fabric filter is the leader of the baghouse technologies. With no moving parts in the basic design and removal efficiencies of greater than 99%, a pulse-jet baghouse can be designed to meet the available footprint for the plant along with the most cost-effective and efficient design for the operation.

With the Dustex® Pulse-Jet Fabric Filter, dirty gases enter the baghouse modules through a side inlet of the baghouse and are evenly distributed throughout the filter media.

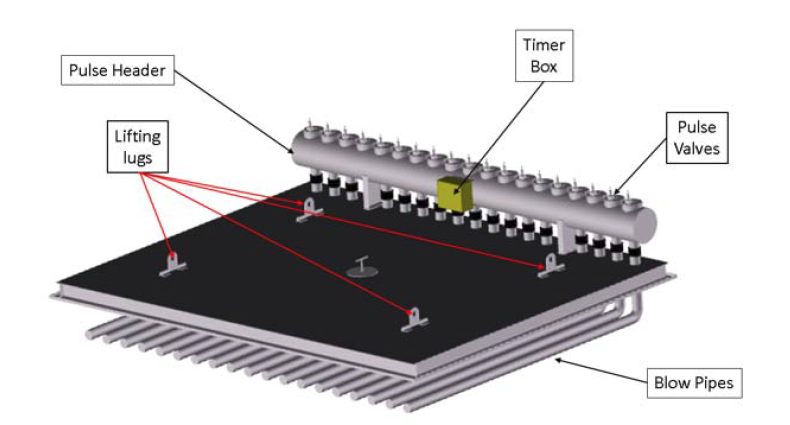

The pulse-jet cleaning cycle is controlled by a solid-state timer or PLC that controls the pulses of the compressed air. Compressed air stored in an air header is released by a solenoid actuated pulse valve and travels from the blow pipes that are mounted above each row of the filer bags into the bags creating a pressure wave. This pulsed air travels down the length of each filter bag in a row, causing a ripple effect, thereby loosening and releasing the dust cake into the hopper.

DUSTEX® PULSE-JET FABRIC FILTER

With the pulse-jet cleaning system a plant operation can choose to clean the filters on-line or off-line. With the ability to program the system for dust removal on a regular and/or on-demand interval, this technology allows for more complete cleaning and reconditioning of the filter bags with minimal pressure fluctuations to the process.

The area above the tube sheet, known as the clean air plenum, serves as the outlet to carry the clean air into the atmosphere. Part of the cleaning system – the blowpipes, are also housed in the clean air plenum. Air headers with solenoid valves sit on top of the clean air plenum. The tube sheet is located below the blow pipes and holds the filter bags in place.

After the gasses pass though the filter, the particulate is collected on the bags and gathered in the hoppers which feed the material handling system. The clean gases then pass through the outlet manifold, ID fan, and stack.

DUSTEX® PULSE-JET FABRIC FILTER FEATURES

With the pulse-jet cleaning system a plant operation can choose to clean the filters on-line or off-line. With the ability to program the system for dust removal on a regular and/or on-demand interval, this technology allows for more complete cleaning and reconditioning of the filter bags with minimal pressure fluctuations to the process.

- Proprietary, advanced side-entry inlet design

- Dustex® Monolithic Floating Pan Top Door

- Capable of long bag design up to 30′

- Split modular or panelized designs

Side Entry Explained

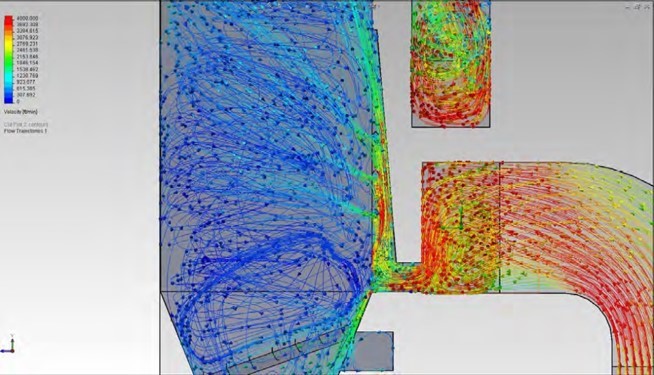

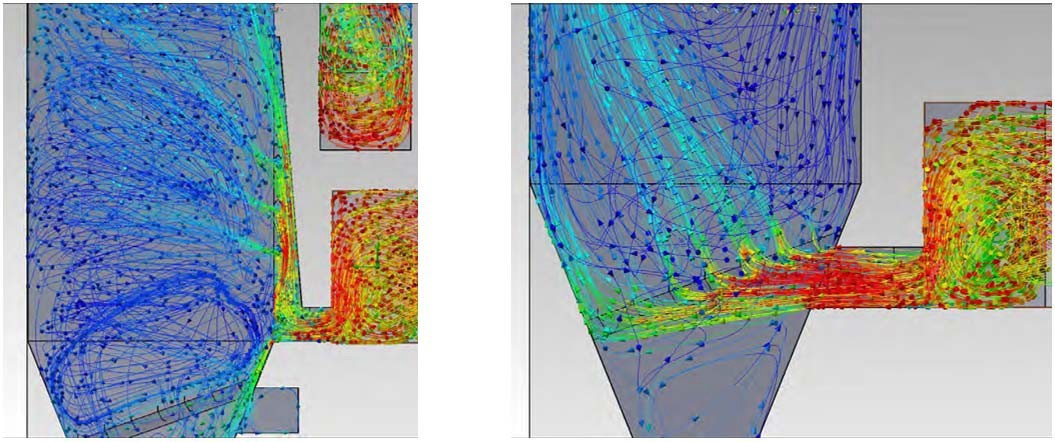

The picture below shows the CFD model comparison of a Dustex® side entry design vs. a traditional hopper entry. As shown in the picture on the left, the side entry design velocities are lower, and most of the flue gas passes from the front wall to the rear wall of the module. In the hopper entry, as shown in the picture on the right, the flue gas velocities are much higher, and the flue gas travels vertically upward to the bags. This leads to bag abrasion and re‐entrainment of particulates back onto the bags. The side entry design can process the same volume of gas but in a smaller footprint, utilizing longer filter bags, and while reducing bag abrasion issues.

DUSTEX® FLOATING PAN TOP DOOR

The patented Dustex® monolithic lift‐off top door has been very well received in the various industrial applications for increased safety & operability:

- Safety during operations – Maintenance lifts the door in one piece with a provided hoist. Personnel simply step down onto the tubesheets to access bags while working in a well-lit and ventilated penthouse – no confined space requirements.

- Easy access for maintenance – The integral cleaning system lifts with the top lid and allows for immediate access to the tubesheets, bags and cages for maintenance.

- No cool down required for penthouse entry – This integral cleaning system also allows for access to the bags without having to handle heavy and potentially hot blowpipes or worry about corroded connections that are common in pulse jet applications.

- No leak design – Patented design allows the bottom pan of the door to expand with the module in hot processes and avoid door warpage that leads to leaking on many designs.

Modular Design

Dustex® designs focus on a Modular approach to minimize field time. Our systems are shipped in the largest pieces possible to minimize field time and amount of time a large crane is at site. This approach allows the baghouse proper to be largely installed in a few days and the finishing work done with a smaller crane. Shop insulation is also possible to eliminate additional field requirements.

Split Module Design

The Dustex® Split Module design is a Patented design utilized for larger flow applications. With the split module design, the modules are shipped to the site with a vertical split. The two halves can then be mated together in the field and lifted directly into the structure. All high side baffling is preinstalled in the units in the fabrication shop and the units are available with shop installed insulation and cladding to further minimize the field time.

Let LDX Solutions Be Your Particular Matter Collection Solution

For A Cleaner World

Further making us the best solution for your Particulate Matter Collection needs is our unparalleled service & life-cycle support. See how our Aftermarket team can keep you online & make you more profitable, regardless of the equipment you currently use.