LDX Solutions Geoenergy® Wet Scrubbers

With our 1st patent issued more than 50 years ago, LDX Solutions is highly experienced in the design and operation of wet scrubbers. We boast a legacy of more than 300,000,000 cfm of emission control systems, and it’s growing! The LDX Solutions team will work with you to design the perfect wet scrubber solution for your needs.

LDX Solutions offers a comprehensive selection of wet scrubbers as part of the Geoenergy® product line of emission control technologies. These include:

- Open Spray Tower Scrubbers

- Packed Tower Scrubbers

Open Spray Tower Scrubber

Wet Scrubber Basics

Wet Scrubbers are an effective technology used to remove a wide variety of contaminants from process gas streams. This includes particulate matter, acid gases, and organic contaminants. Examples of acid gases include sulfur dioxide (SO2), hydrogen chloride (HCl), and hydrogen fluoride (HF) while examples of organic gases may include odor-causing compounds such as methyl mercaptan (CH3S) or ethanol (C2H5OH).

Wet Scrubber

The Wet Scrubbing System

Wet scrubbers work by contacting the contaminated gas stream with a liquid solution, usually water, to effect removal of the contaminant from the gas stream. This removal occurs in one of two principal ways. If the contaminant is a particulate the removal mechanism is by a physical separation of the particles from the gas stream, i.e., by impaction and diffusion. If the contaminant is a gas, then the removal mechanism is absorption of the gas into the liquid.

In some cases, wet scrubbers can be used to do both simultaneously. For example, in a process gas stream coming from a coal-fired boiler the gas stream contaminants may include both sulfur dioxide (gas) and fly ash particulate (solids) and both can be captured in a single wet scrubbing system.

A Variety of Wet Scrubber Designs

Wet scrubbers have been used in industry for many years and, as a result, there are a wide variety of designs. Most employ water or an aqueous solution to perform the scrubbing requirement whether it is gas absorption or particulate removal. However, in some specialized process applications, alternatives to water such as oil have been used.

RCO & Wet Scrubber

Critical Choices & Challenges

On the surface, scrubbers are simple machines. However, regardless of the process or application each project presents a myriad of choices and challenges to be resolved during the design, installation, and start-up phases. The success of the project is strongly dependent on how each is handled, and experience is critical in making the right decisions and therefore ensuring that success. LDX Solutions has the experience.

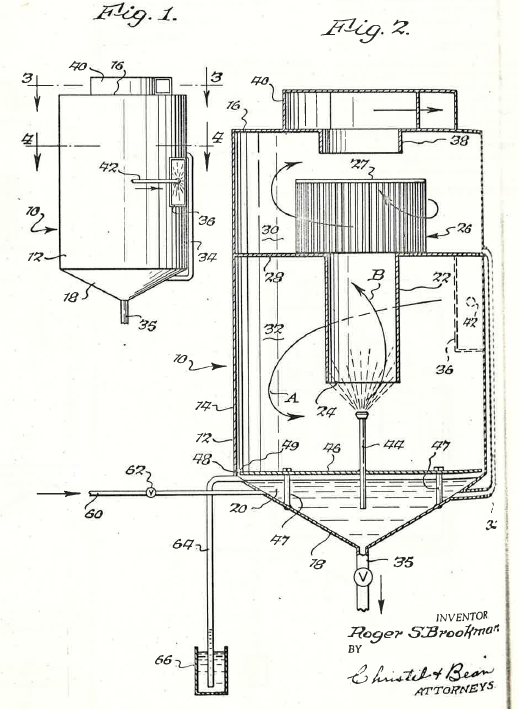

From 1973 Patent

Ammonia / Sulfuric Scrubber

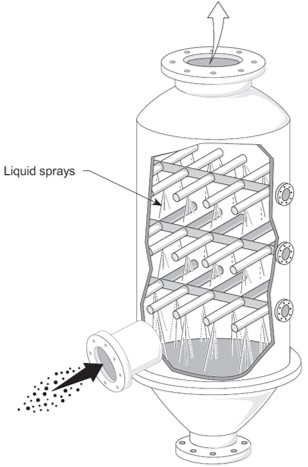

LDX Solutions Geoenergy® Open Spray Tower Scrubbers

Open spray tower scrubbers are vertical-flow vessels that are equipped with multiple levels of hydraulic spray nozzles. The spray nozzles provide a “shower” of scrubbing liquid to intimately contact the upward flow of contaminated process gas. These scrubbers are very effective in absorbing contaminants such as acid gases and operate with a very low pressure drop.

The low-pressure drop is a direct result of low velocity operation without the use of internal packing. Open spray tower scrubbers can achieve up to 99% removal of acid gases or organic compounds. In addition, because of the open design, this type of scrubber is tolerant of particulate in the gas stream and can provide some degree of particulate removal.

LDX Solutions Geoenergy® Packed Tower Scrubbers

In applications where particulate fouling is not a concern LDX may offer a packed tower scrubber. Like the open spray tower scrubbers discussed above, packed tower scrubbers are normally an upflow vertical device with the gas stream flowing counter-current to the absorbing liquid.

The difference is that packed tower scrubbers have a layer of scrubbing media within the vessel that is designed to enhance contact with the contaminated gases. This media is wetted by a distribution header located on top of the media bed. The scrubbing media may be a random “dumped” media such as saddles or rings or it may be a structured type media. In either case packed tower scrubbers do have a higher pressure drop than the open spray chamber scrubber but may offer even higher acid gas or organic compound removal efficiencies.