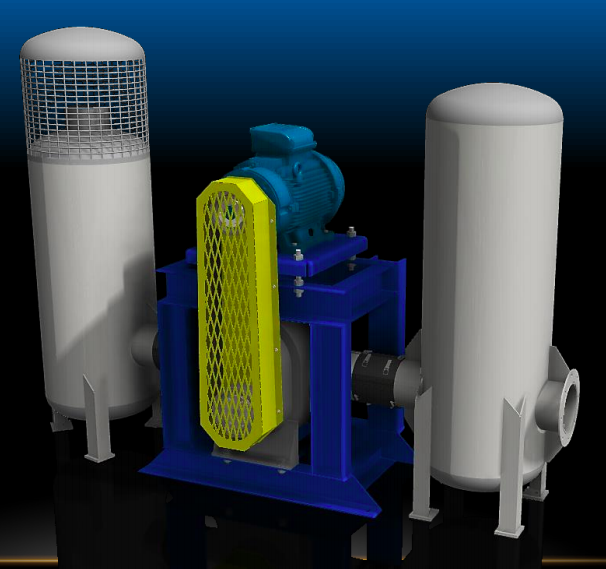

Western Pneumatics designs high pressure pneumatic conveying systems which use positive displacement blowers to create the air and pressure needed to move product efficiently.

Blower Operation

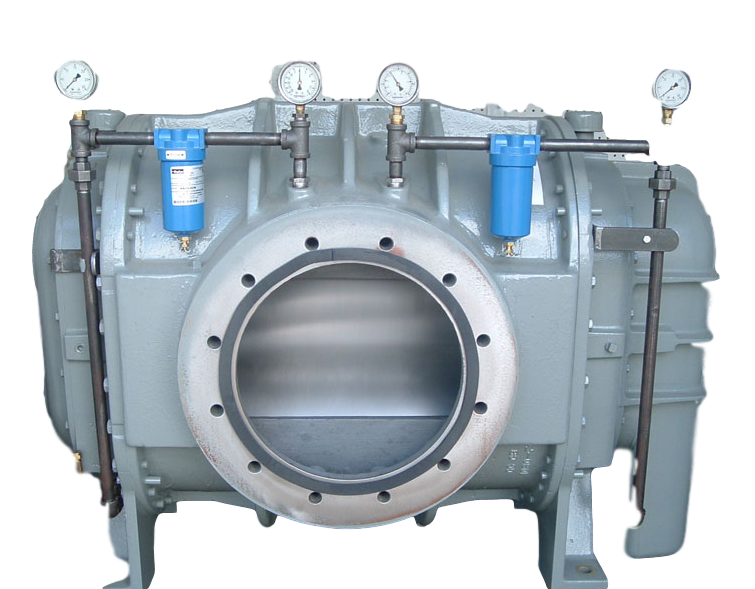

Positive displacement blowers are designed with two internal lobes which rotate to produce air used to convey product. The lobes are machined and the housing they rotate in is designed to minimize air escaping past the lobes as they rotate. Blowers are specifically sized for air volume and pressure capacity and only displace air, not product.

The blower is driven by a motor with a belt drive, an inlet and discharge silencer are connected to the inlet and outlet of the blower openings to attenuate noise created by the blower.

A Western Pneumatics high pressure system is designed with a low air-to-material ratio, a large mass flow of product can be moved long distances and to multiple destinations.

The high pressure system is an energy efficient and clean method to move product.

Blower Inspection and Loaner Program

Please call us at 541.461.2600.

After

After

Blower Field Inspection & Loaner Program

Overpressure, overhung load, poor lubrication and no blower pressure control panel are the chief culprits for blowers falling into disrepair.

Western Pneumatics carries a large stock of rebuilt blowers of many sizes and major manufacturers. Our technicians do field inspections and determine the general condition of your blower. If your blower is a candidate for repair, we can offer a loaner blower while your blower is repaired.

While it is good practice to always have a spare blower in case of emergency, our inventory of blowers at Western Pneumatics can help relieve the pain of a downed system and or plant.

After

Blower Repair Program

The blower does not handle material, but use of the blower creates wear and which can be repaired at a fraction of the cost of a new blower. Western Pneumatics rebuilds Sutorbilt, Gardner/Denver, Roots, Tuthill and Kaeser brand blowers.

The discovery portion of the repair program includes a blower being disassembled and inspected for wear and mechanical failure. A thorough inspection report is sent to the customer for review and approval to repair the blower