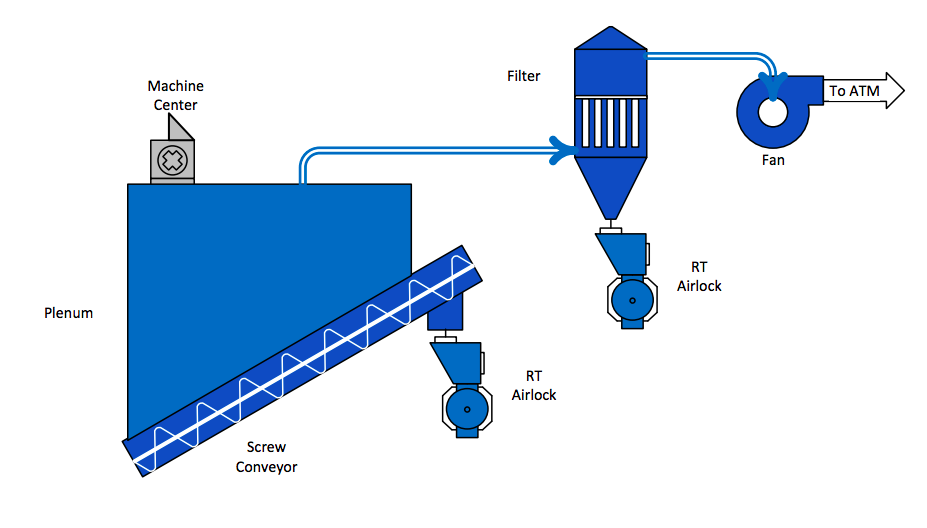

Air-assist systems are designed to improve the hammermill throughput and geometry of the product. A hammermill grinds up (sizes) the product, more product can be ground up by pulling air through the hammermill. A plenum mounted above a conveyor is located below the hammermill. A majority of the product falls into the conveyor, the conveyor discharges the product through an airlock into a downstream piece of equipment. A filter is mounted remotely from the plenum, air and some dust are pulled to the filter with the assist from a fan located after the filter. The filter utilizes either bags or cartridges for the filter media as air from the plenum can be dusty. The filter media captures the dust on the outside of the filter media, a compressed air cleaning system built into the filter blows the dust off the filter media which allows dust to fall back into a downstream device. An airlock is located at the bottom discharge of the filter. Clean air exits the top of the filter and is directed to a fan which is creating the motive force for this system design. The fan discharges clean air to the atmosphere.