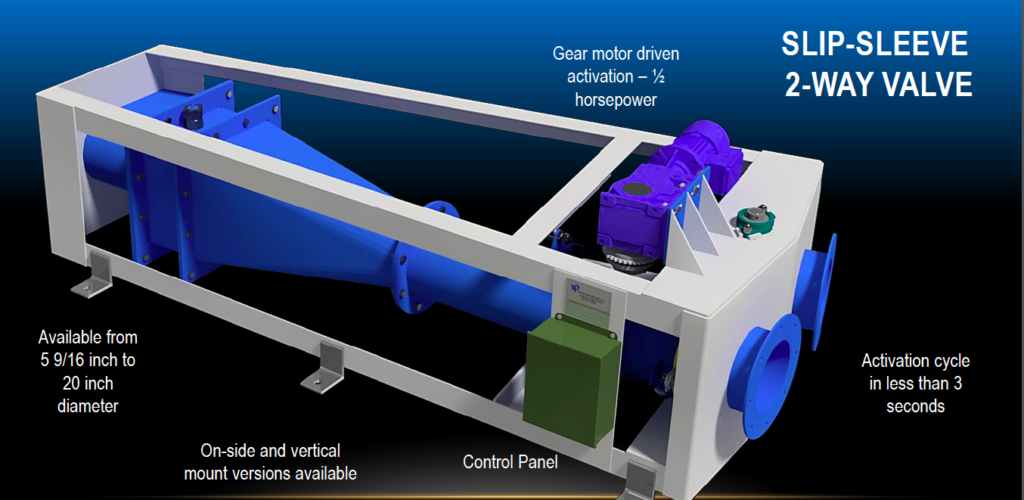

With 40+ years in the business, LDX Solutions is your number one source for valves to allow the high-pressure systems to discharge to multiple locations. The valve includes an inlet connected to a pivoting transition section, a machined slip-sleeve section which connects to multiple stationary discharge ports, the support frame, and a control panel with electrical panel. The ports are connected to piping routed to different destinations. The valve and surrounding pipe must be adequately supported as the valve components are machined to handle the air pressure in a high-pressure system.

Product flow must be stopped prior to disengaging the slip sleeve section and moving the transition section to another port. High pressure system air discharges from the valve assembly when changing to different ports. When the linkage of the valve moves the valve into position, the slip-sleeve extends over the new port inlet. Material flow is turned back on when the slip-sleeve is fully positioned over the new port inlet.

The valve transition is typically moved by an electric motor but can be moved manually if access is available. Valves can be mounted at ground level or in the air, when mounted at elevation, electrical activation is most common.