LDX Solutions Dustex® DSI

LDX Solutions offers a large selection of Dustex® DSI systems that are based on our years of experience and expertise in SO2, SO3, HCl, and HF mitigation. We also have extensive experience working with companies and their engineering firms’ specifications for custom DSI systems.

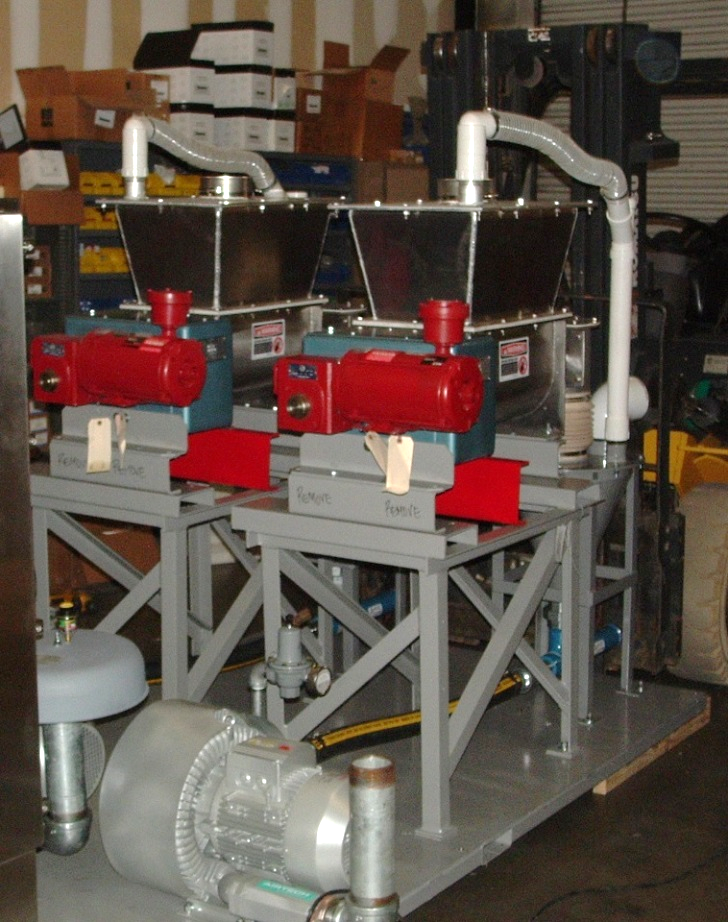

So, whether your plant needs are standard or custom, Dustex® DSI systems are designed to meet the rigorous requirements of a typical plant environment, and to operate for extended time periods with little or no maintenance. Our top-quality components have been chosen for their reliability and cost-effective performance.

DSI Basics

Our own Dustex® branded technologies are well proven and have a long track record to help with almost any type of contaminant found in the air streams from cement facilities and typically include:

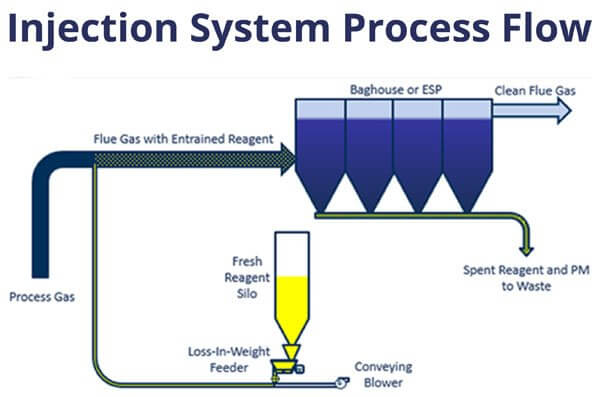

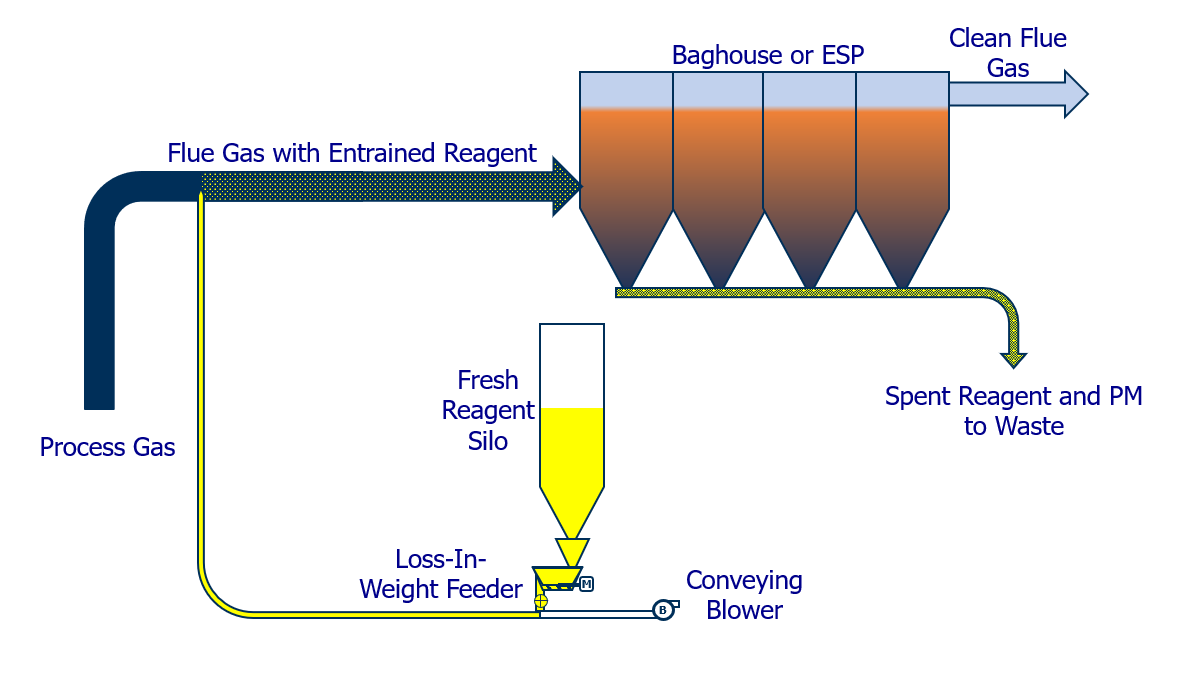

Dry Sorbent Injection Systems involve the injection of a dry sorbent into the flue gas ductwork following the boiler to reduce concentrations of acid gases SOx, HCl and HF which are regulated to prevent acid rain. These acid gases react directly with the dry sorbent, which are collected in a downstream particulate control device. Because a separate scrubber vessel is not needed, capital costs are minimized.

Critical advantages include its low capital cost and a smaller footprint when compared with other technologies; however, these capital cost savings are partially offset by lower reagent utilization, resulting in higher operating costs.

The Dry Sorbent Injection System

A Dry Sorbent Injection (DSI) System is engineered to have a powdered alkaline sorbent, like hydrated lime or sodium bicarbonate, pneumatically conveyed from a storage silo and injected into the flue gas exhaust duct where it reacts with acid gases to form a salt. The product is then captured by a fabric filter baghouse or electrostatic precipitator and removed with the particulate matter.

Dry Sorbent Injection (DSI) System Advantages

A Dry Sorbent Injection System is a simple system with low capital cost and high reliability. There are multiple reagents available: Hydrated Lime: Ca(OH2), Sodium Bicarbonate: NaHCO3 and Trona: NaCO3, for acid gas mitigation. Dry Sorbent Injection Systems are generally applied when lower removal efficiencies are required, or on smaller plants where the capital cost for other scrubber types may not be justified. DSI Systems typically provide removal efficiencies for SO2 up to 60% and greater than 99% HCl reduction.

SO2 Reduction with a Dry Sorbent Injection (DSI) System

The reduction of SO2 concentrations utilizing a dry injection system requires lower temperature and more time for optimal reaction than other flue gas constituents. Hydrated Lime reacts with SO2 below 350°F, while Sodium Bicarbonate and Trona become cost effective at higher temperatures.

Benefits of Dry Sorbent Injection

- Cost-effective

- Dependable, proven technology

- Top quality, utility grade components

- Effective across a wide range of fuels and plant configurations

- Standard equipment design to reduce cost and minimize delivery times

- Designed and built to meet utility and A/E specifications

- High availability and low maintenance

- Operational flexibility

- Fully automated, hands-free operation

- Fail-safe interlocks and alarms

- Systems can be designed for use with hydrated lime or sodium bicarbonate reagents

LDX Solutions Dustex® Standard and Custom Designed DSI Systems

LDX Solutions will meet the strict specifications required for your unique application and ensure that it will operate within all limits required. Our team of project engineers and designers will work closely with your engineering team to ensure that all specifications and requirements are built into the Dustex® DSI System, ensuring seamless integration into the plant where it will be installed.

LDX Solutions DustexTM DSI Advantages

- Cost-effective

- Dependable, proven technology

- Top quality, utility grade components

- Effective across a wide range of fuels and plant configurations

- Standard equipment design to reduce cost and minimize delivery times

- Designed and built to meet utility and A/E specifications

- High availability and low maintenance

- Operational flexibility

- Fully automated, hands-free operation

- Fail-safe interlocks and alarms

- Systems can be designed for use with hydrated lime or sodium bicarbonate reagents