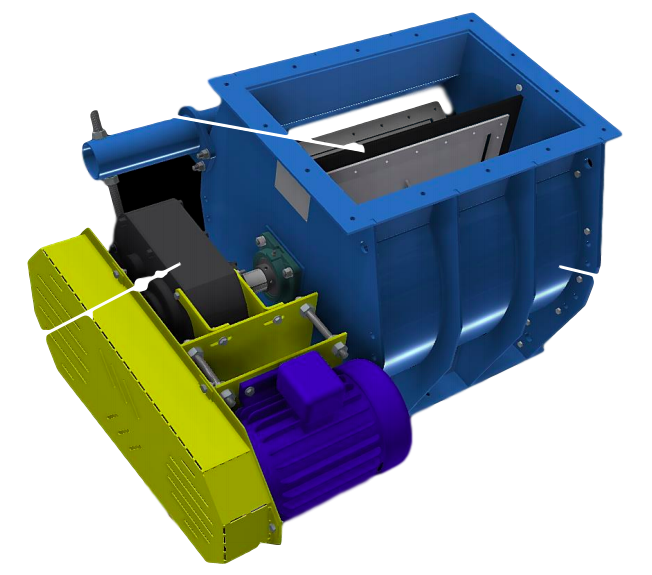

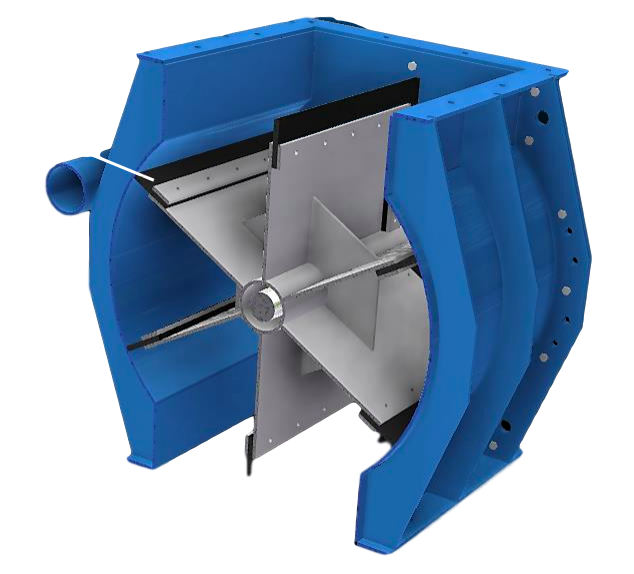

RUBBER TIPPED AIRLOCKS

A rubber tipped airlock is a rotary valve, it has an internal rotor assembly turning at a specific speed. The rubbers on the sides and ends of each blade rub against the housing creating an airlock. The pockets in the rotor are partially filled, as the rotor turns, it discharges product into the device below. The rubber tipped airlock is most effective when air pressure is below 1 PSI. Airlocks are used at the discharge of cyclones or conveyors to move product and control air flow. Airlocks are designed and sized to handle metered volumes of product. Product volume determines the size of the airlock, plugging above the airlock can occur if not sized correctly. An airlock is driven by a direct or belt driven drive, most all of our future airlocks will be direct driven. The rectangular inlet and discharge airlock must have an infeed chute to best introduce product into the rotating rotor pockets.

STANDARD AIRLOCK

After

After