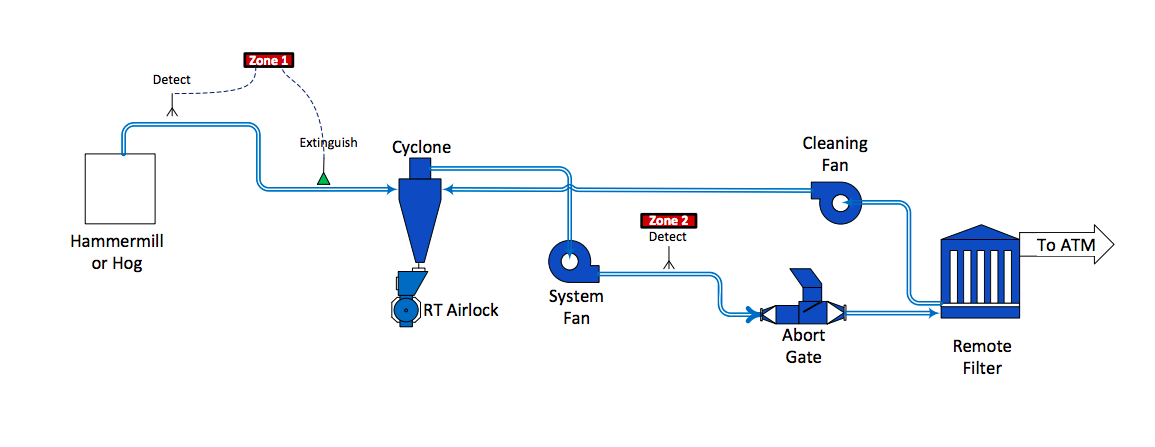

Hammermills or hogs process (size) a various mass flows of products, the hammermill throughput and geometry of the product is improved by pulling air through the hammermill. A low pressure system is connected directly to the hammermill bottom discharge pan section and product is pulled from the hammermill to a primary cyclone with an airlock below the cyclone. Most all of the material from the hammermill or hog is discharged out through the airlock below the cyclone. Dusty air is pulled from the cyclone to the motive fan, the fan then pushes the dusty air through an abort gate and into a remote filter. The remote filter’s cleaning system fan pulls dust collected on the inside of the filter media and blows the dust back to the primary cyclone. All material ends up discharging out of the airlock below the cyclone. The filter discharges clean air to the atmosphere.

SPARK DETECTION –ZONE 1 & 2

A spark detection and extinguishment system is installed an most all dust control systems. Small dust particles mixed with air can be explosive when a spark heat energy is introduced. The cyclones or filter receivers possess the right environment for the possibility of a dust explosion.

A spark detector is mounted on the sides of a dust system pipe, as a spark passes the detector, the detector senses the spark and sends an electrical signal to the spark detection control panel. The control panel sends a signal to the extinguisher mounted in the sides of the pipe downstream of the detector location. The wet extinguishment system sprays a mist of water into the pipe and puts out the energy of the spark.

A second zone of spark detection is typically mounted after the extinguisher zone, if a spark is detected with the second zone of detection, it sends an electrical signal to the control panel which then sends a signal to the abort control panel which cuts energy to the abort gate magnet allowing the abort gate to drop. The gate forces air and material out of the normal route of the piping and either into the atmosphere or into receiver by-pass piping.