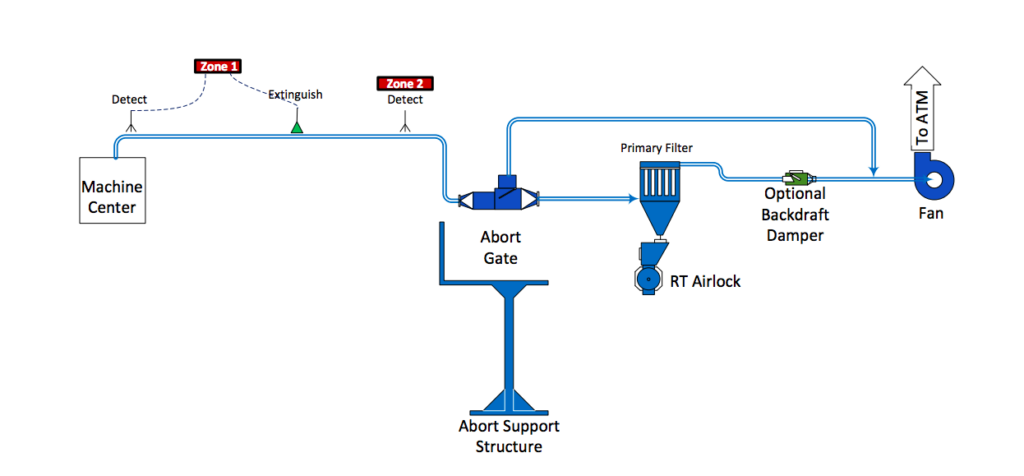

A spark detection and extinguishment system is installed an most all dust control systems. Small dust particles mixed with air can be explosive when a spark heat energy is introduced. The cyclones or filter receivers possess the right environment for the possibility of a dust explosion.

A spark detector is mounted on the sides of a dust system pipe, as a spark passes the detector, the detector senses the spark and sends an electrical signal to the spark detection control panel. The control panel sends a signal to the extinguisher mounted in the sides of the pipe downstream of the detector location. The wet extinguishment system sprays a mist of water into the pipe and puts out the energy of the spark.

A second zone of spark detection is typically mounted after the extinguisher zone, if a spark is detected with the second zone of detection, it sends an electrical signal to the control panel which then sends a signal to the abort control panel which cuts energy to the abort gate magnet allowing the abort gate to drop. The gate forces air and material out of the normal route of the piping and either into the atmosphere or into receiver by-pass piping.

LOW PRESSURE FILTER BYPASS

In normal operating conditions, process air is pulled from a machine center through the filter with a fan on the clean air side of the filter. A spark detection system is located between the machine center and prior to an abort gate and filter. In an abort event, process air is diverted away from the primary filter and into the piping after the filter. When the abort gate internal blade drops, it re-directs air around the filter, the fan will continue to operate and clean out all piping from the machine center(s). An optional back draft damper can be placed directly after the filter.