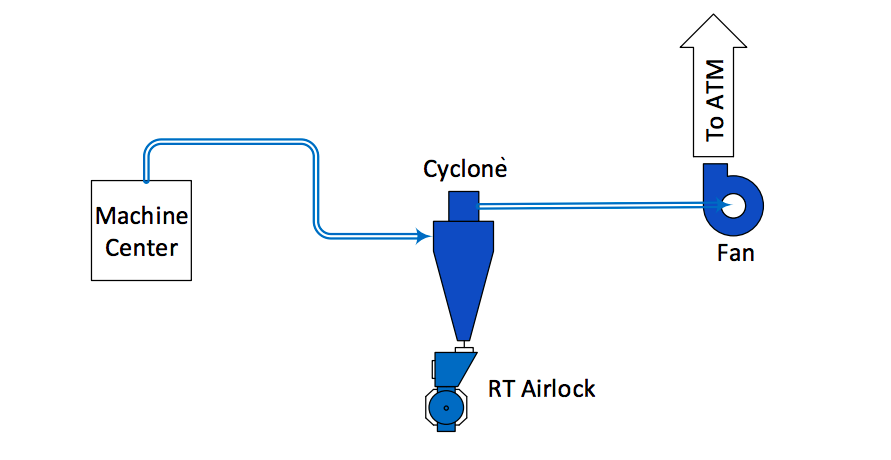

WP has over 35 years of designing, manufacturing and installing low pressure negative systems, many different types of products have been conveyed which include wood, agricultural and minerals. Various products require require specific designs to move it in a cost effective and efficient manner. A negative Low Pressure system begins at the machine center generating waste, suction air pulls waste from the machine center, air and waste are pulled to a receiving devise, waste is discharged out the bottom of the receiving devise while air exits the top of the devise. The fan creating the motive air is located after the receiver and is moving clean air, there is no waste material in the air stream. The fan discharges clean air to the atmosphere. A single fan can handle multiple machine centers.

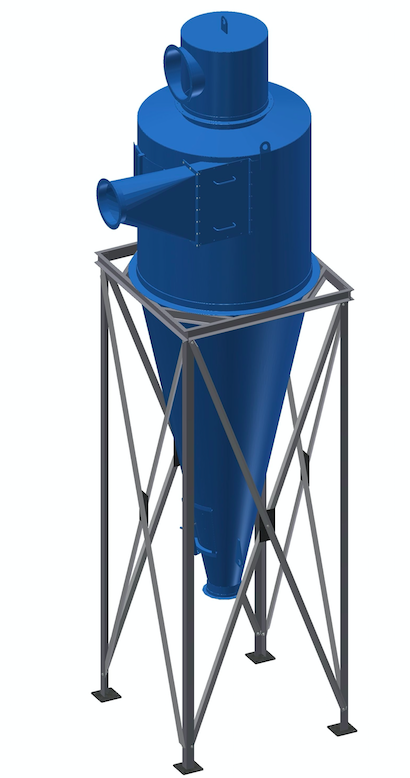

THE RECEIVER & AIRLOCK

Air and dust are pulled to the receiver, the receiver is sized based on the volume of air. When air and material enter the receiver, it travels on the inside of the round receiver. Centrifugal force separates the waste from the air stream. Waste discharges out the bottom of the receiver, air exits the top of the receiver.

After

After

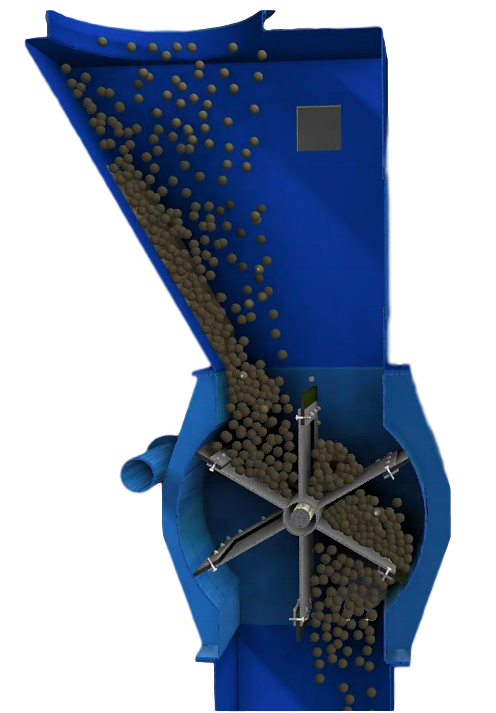

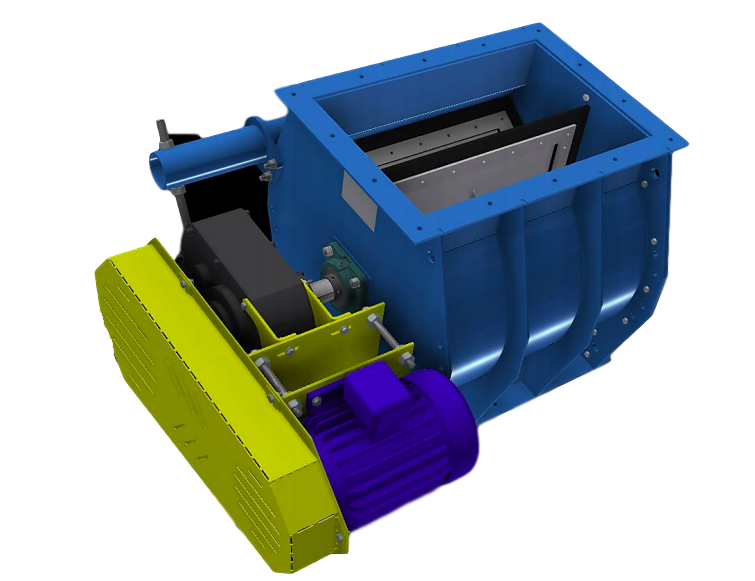

RUBBER TIPPED AIRLOCK

An airlock is placed at the bottom discharge of a receiver, the airlock permits waste to discharge through the airlock, while air is forced up and out the top of the receiver.

Airlock internal blades may be rubber tipped or machine tipped. Airlocks have various sizes, the size of the airlock is based on the waste volume. The larger the waste volume, the larger the airlock. Airlocks are not a metering devise

After

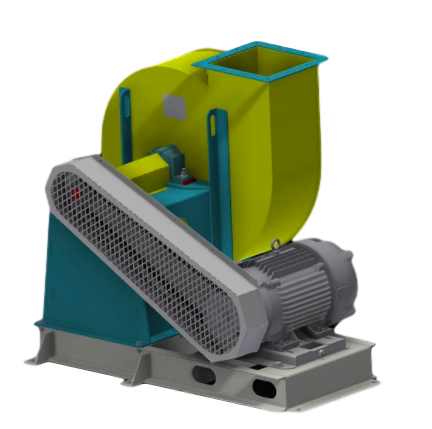

THE FAN

Air and suction are created by a centrifugal fan design. The fan is located after the machine center and receiver making this a negative system. The fan can be designed for light dust handling or clean air and a more efficient fan wheel can be utilized. The fan discharges air to the atmosphere.