Machinery Group

The Machinery Group of LDX Solutions provides various types of Western Pneumatics finger jointers, grinders, wood handling machines and technical support. Click on links below to learn more!

Finger Jointing & Grinding

Structural And Molding/Millwork

- Finger jointing and grinding technicians for troubleshooting, maintenance & programming

- Training for finger jointing and grinding

Finger Jointing Systems

- Heavy/High Production FJ

- Structural Finger Jointer

- Finger Jointer Customization

- Technical Support Team

Grinders

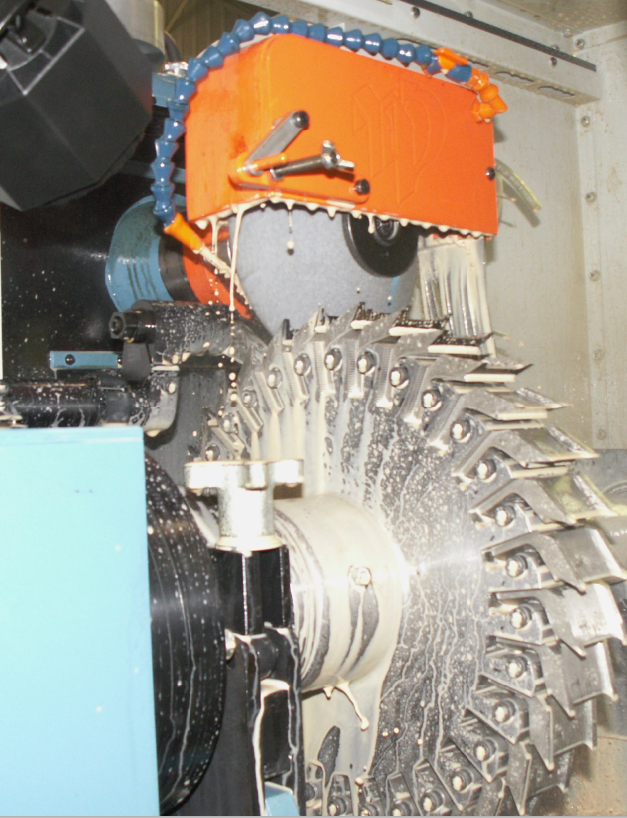

The model GR2500 is a fully automatic grinder with a new “Quick Change” arbor system. It features 4-Axis cutter grinding, a quick adjust probe, heavy duty linear carriage bearings, and much more.

Saves Time

Fully automatic un-supervised grinding allows your operators to walk away and attend other tasks while the grind cycle happens automatically.

GR 2500 Grinder

Versatile

With our interchangeable arbor system, a catalog of 60+ available

arbors and a full machine shop that can make custom arbors, the

GR2500 adapts to your needs now and into the future.

Better Cut Quality

High precision grinding that is uniform from one knife to the next means all knives share the load equally which often improves quality of cut.

Increase Tool Life

High accuracy and repeatability means you can grind only what’s needed and avoid over grinding.

Saves Money

Our expert technicians can train your grinder room staff and help you optimize your tool grinding recipes.

GR 3500

GR 2500

Are You Interested in Analysis, Assessment & Field Inspections?

Best Parts & Unbeatable Service

LDX Solutions had years of experience providing inspection and mechanical services to a wide range of partners across a myriad of industries. Our job is to find the big and small issues that will take equipment offline. We have parts for not only our engineered and patented systems but others as well.