Chemical Production Requirements

LDX Solutions has a variety of Lundberg chemical processing solutions to address both byproduct recovery and chemical production requirements for an assortment of processes.

Byproduct Recovery & Chemical Production

Byproduct recovery is an important source of revenue for many facilities and LDX Solutions has a full range of equipment to optimize the recovery of valuable materials, including tall oil soap and turpentine. We also provide systems to produce oxidized white liquor and sulfur dioxide, which can be repurposed for a broad range of industrial and commercial uses.

White Liquor Oxidation

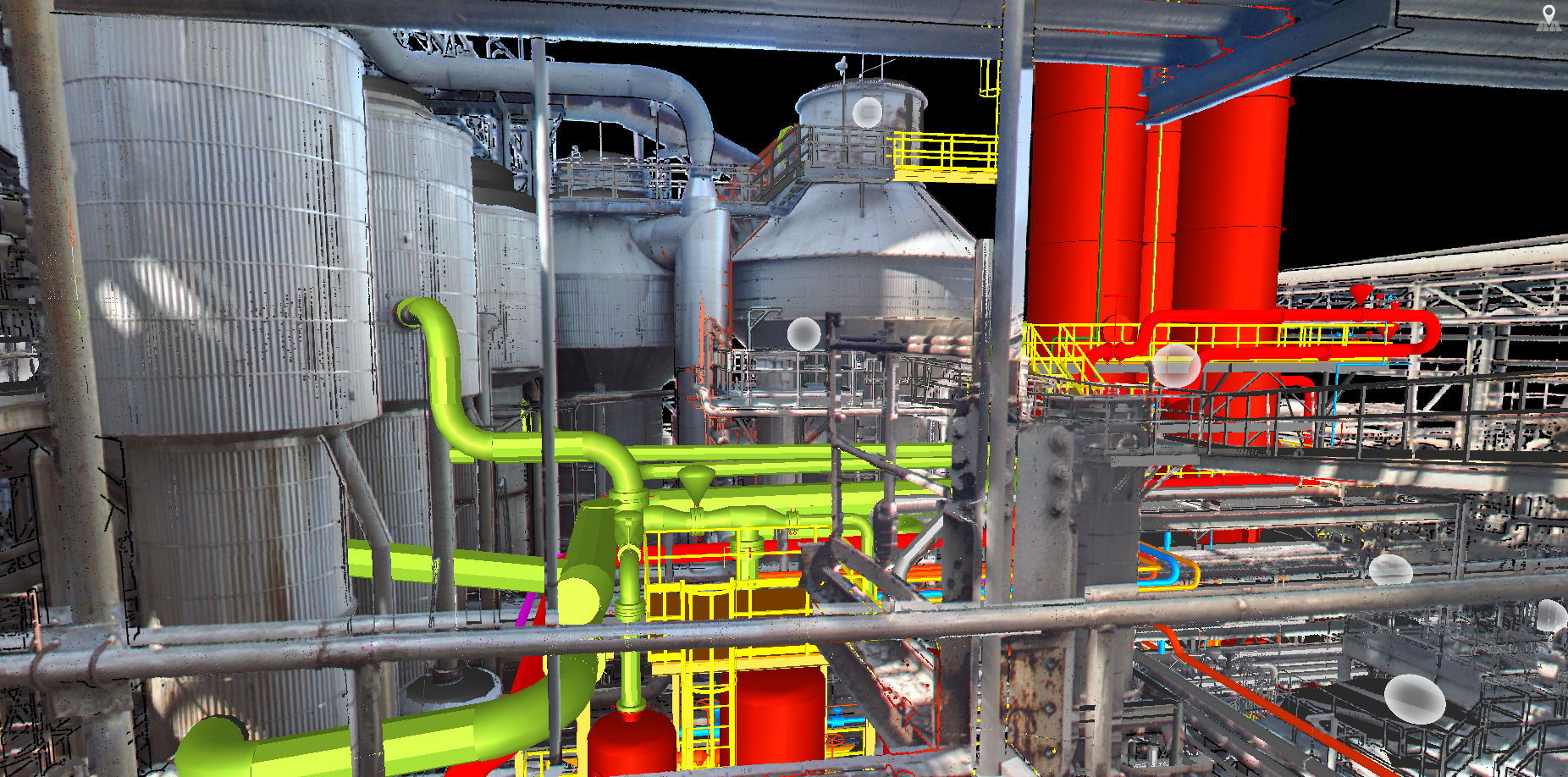

Air Sparged Oxidizer

Air Sparged Oxidizer

LDX Solutions offers pulp and paper clients both air and molecular oxygen white liquor oxidation systems. Our patented air oxidation system is a two-stage process within one tank to maximizes chemical conversion efficiency.

When White liquor comes into contact with oxygen, sodium sulfide is oxidized to form sodium thiosulfate. The oxidized liquor becomes a caustic source for a number of different mill systems, including oxygen delignification of pulp and incinerator flue gas scrubbing.

The molecular oxygen oxidation process takes place under high pressure and temperature. Molecular oxygen is sparged into the feed white liquor. This mixture is passed through a series of serpentine pipes to induce mixing and give residence time for the reaction to occur.

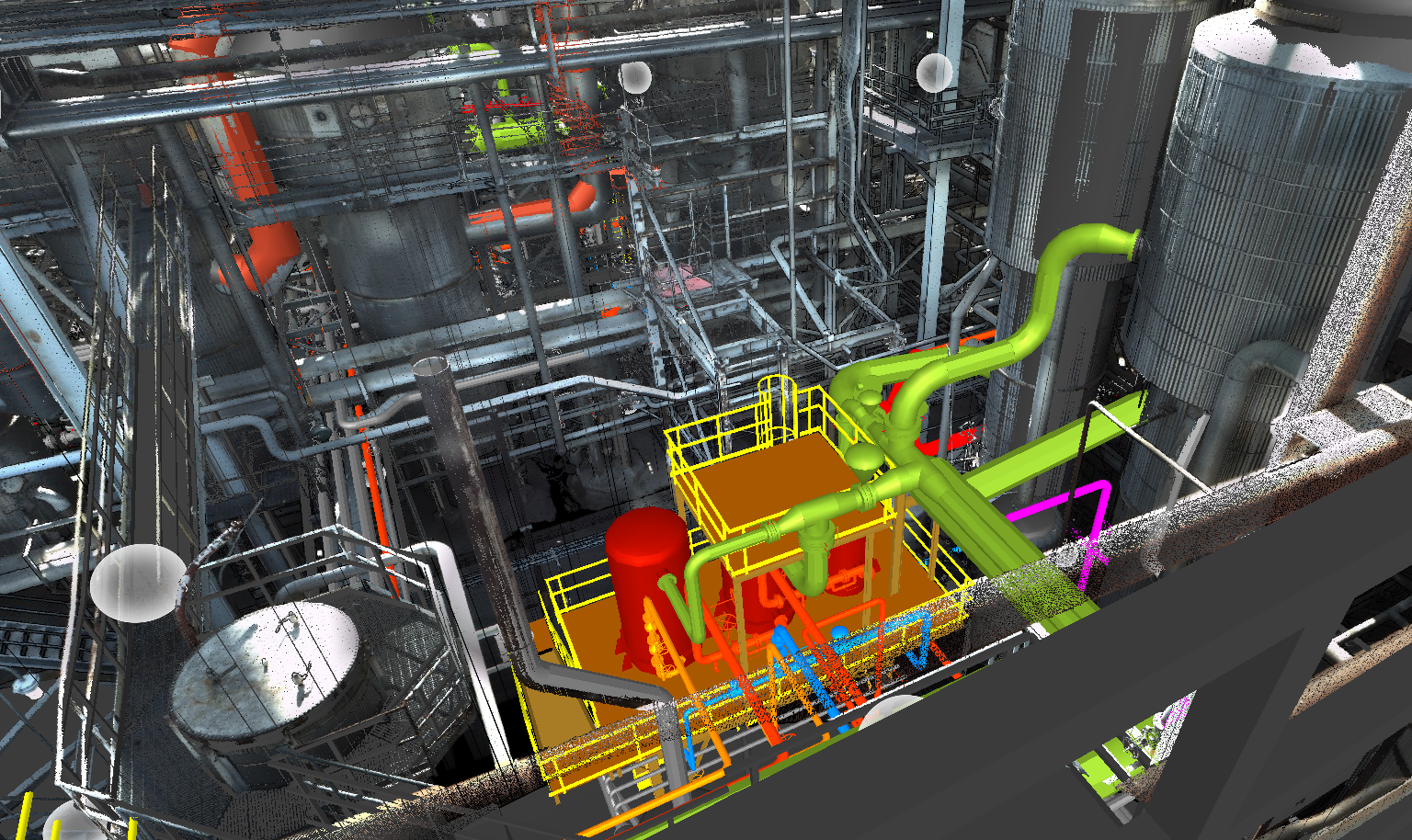

The Molecular Oxidation System

The molecular oxidation system can be supplied as a pre-piped skid- mounted module including all instrumentation and valves. It is designed to be mounted on the purchaser’s foundation and connected to the service piping.

Molecular Oxidizer Skid

Molecular Oxidizer Skid

SO2 Cooling & Absorption

The generation of sulfur dioxide from burning elemental sulfur has a wide range of applications. It is used in the pulping process as well as other industries from wet corn milling to soap manufacturing. Our system is suitable for all these applications.

SO2 Cooling and Absorption

SO2 Cooling and Absorption

The size of the system is suited to the mill application, from 1 ton per day to above 60 tons per day of sulfur dioxide.

Feed to the sulfur burner system can be solid sulfur or molten sulfur. The molten sulfur is fed directly or from a sulfur melter and is combusted in a pressurized chamber using atomizing air. This results in a high combustion temperature as well as a high sulfur dioxide concentration.

The combustion products may be cooled for absorption into water or a caustic solution. The hot sulfur dioxide gas may be air quenched and sent to a sulfuric acid plant. The system is designed for complete automation so that changes in the sulfur dioxide demand are compensated in the amount of sulfur burned. The system is operated under pressure so that an induced draft fan is not required.

Sulfur Burners

The generation of sulfur dioxide by combusting elemental sulfur has a wide range of industrial applications: fungicide, disinfectant, and food preservative for fruits and wine. It is also used in some wood pulping process and as a bleaching agent for paper, textiles, oils, etc. Our system can utilize either solid sulfur or molten sulfur as a basis for the process. The molten sulfur is combusted in a pressurized chamber using atomizing air. This results in a high combustion temperature as well as a high sulfur dioxide concentration, minimizing sulfur trioxide generation. The system is designed for complete automation so that changes in the sulfur dioxide demand are compensated for directly in the amount of sulfur burned.

Sulfur Burner with Heat Recovery

Sulfur Burner with Heat Recovery

Tall Oil Soap Recovery

Tall oil soap is a valuable by-product as well as a toxin to the wastewater treatment system. Efficient separation, collection, and processing contribute to mill profitability and environmental compliance.

Our line of Lundberg products address the collection and conditioning of tall oil soap from the many potential locations in the pulp mill. We design and supply weak liquor tank soap collection systems, evaporator soap skimmers, liquor removal systems, soap concentrators and foam breaking equipment.

LDX Solutions also designs and supplies complete tall oil acidulation systems and the modular components. If there is a need for conditioning ahead of existing batch or continuous reactors, we can provide a design to maximize yield and efficiency.

Continuous Decanting CTO Plant

Continuous Decanting CTO Plant

A Valuable Byproduct

In kraft softwood pulp mills, tall oil soap is a valuable byproduct as well as a toxin in the wastewater treatment system. LDX Solutions has a full range of equipment to optimize the recovery of soap from black liquor, de-aeration of the recovered soap, and removal of black liquor from the soap. Not only do these systems provide a better quality of soap, also reduce shipping costs and the chemical consumption during acidulation.

Floating Skimmer Modules

Floating Skimmer Modules

Turpentine Recovery

LDX Solutions is the leader in the design and installation of turpentine recovery systems. We have over 100 projects completed from installation of full systems to upgrading existing turpentine collection systems.

Our systems are found throughout the pulping industry in many different designs. The goal is to maximize turpentine collection from all potential pulping and condensate sources and minimize losses to the water treatment system.

The turpentine collection system components are designed to meet the variable process conditions and be integrated into the NCG system. As a PSM chemical, it is also important to design the physical plant to adhere to PSM requirements.

Decanting and Storage System

Decanting and Storage System

Turpentine Recovery

Turpentine Condensing and Storage

Turpentine Condensing and Storage

LDX Solutions is the leading supplier of turpentine recovery systems. Our systems are designed to recover turpentine from digester flash and relief gases, thermomechanical pulping heat recovery systems and flash digester pre-evaporation systems. Our systems provide dry, low sulfur turpentine suitable for sale.

Ash Treatment Systems

LDX Solution’s Ash Treatment System (ATS) processes the sulfated ash from the chemical recovery boiler precipitator to remove potassium and chlorides and allows for the recovery of sodium sulfate crystals.

The ATS system is designed to reduce the concentration of chlorides and potassium in the recovery cycle. Reducing the potassium and chloride content will effectively increase the “sticky temperature” for the ash in the boiler flue gases, thus reducing both the frequency of boiler washes and steam consumption for soot blowing. The ATS system is designed to provide 85% sodium recovery and 85% removal efficiency on both chlorides and potassium from the incoming ash feed. The ATS system can be integrated into you existing evaporator set, to improve steam utilization and reduce operating costs.

ATS Liquor Flash Tank

ATS Liquor Flash Tank

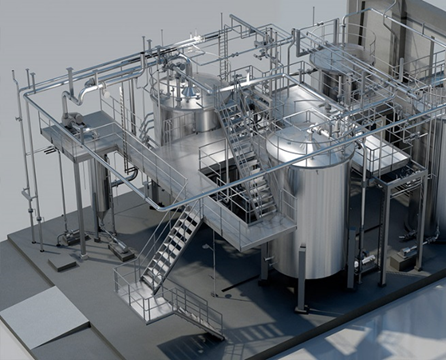

A State-Of-The-Art Lundberg® Design

Ash System Process Island

Ash System Process Island

LDX Solution’s ash treatment system is a state-of-the-art Lundberg design for plants looking to reduce chloride and potassium levels in their recovery cycle. Our systems are designed to maximize the recovery of sodium back into the system while minimizing chloride and potassium levels. These systems can be a key part of strategies to maximize your recovery boiler’s uptime while minimizing chemical makeup costs.

LDX Product and Solutions for a Cleaner World

Find out how LDX Solutions can Optimize your Industry

Further making us the best solution for your Chemical Processing needs is our unparalleled service and life-cycle support. See how our Aftermarket team can keep you online and make you more profitable, regardless of the equipment you currently use today.