What is a Baghouse

A fabric filter, commonly referred to as a baghouse, is a dust collection device that houses filter bags, also known as filter media, which removes particulate matter/dust from process gases.

Baghouses are utilized in many industrial applications to capture particulate matter

that is produced by a facility before it is emitted into the environment.

How It Works

The dirty gas stream enters the baghouse either via an inlet air plenum or directly into the hopper. Upon entry, the larger particulate matter drops directly into the hopper below, due to a decrease in conveying velocity. As the gas flows upward into the bag mass, the finer particles attach to the outside of the filter bags, allowing only the clean air to pass through the filter media, into the clean air plenum, and then released into the environment.

Once a layer of dust cake is built on the outside of the filter bags, bag cleaning takes place to regenerate the permeability of the filter media. The dust cake being built actually adds to the filtration efficiency of the system but eventually, this can begin to work against the system and provide too much resistance to the flow. The buildup of the dust cake on the filter bag increases the differential pressure measured over the baghouse which then prompts the cleaning process.

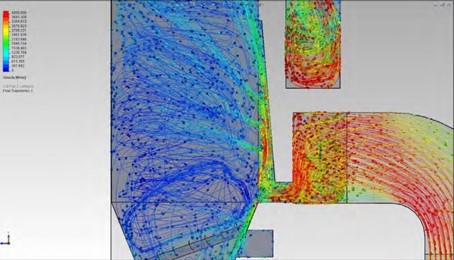

CFD Model of Side-Entry Inlet Configuration

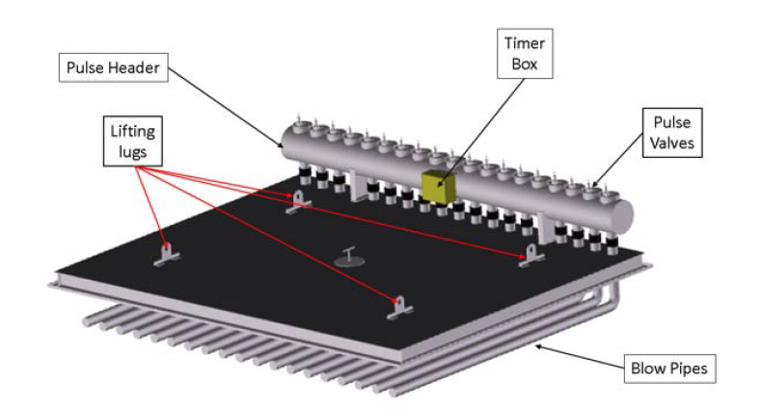

Dustex® Floating Pan Top Door

The upper body of the fabric filter, known as the clean air plenum, serves as the outlet to carry the filtered air into the atmosphere. Part of the cleaning system – the blowpipes, are also housed in the clean air plenum. Air headers with solenoid valves sit on top of the clean air plenum. The tube sheet is located below the blow pipes and holds the filter bags in place.

The cleaning system consists of double diaphragm valves connected to the blowpipes and mounted over the bags. When cleaning is needed, there is a release of air stored in the air header through the blow pipes. This pulse of air comes from the actuation of the double diaphragm valve. Pressurized air is released to the dirty bags one row at a time. This pulse of air breaks the dust cake on the filter bags, releasing the dust into the hopper thus restoring normal flow through the filter media. Cleaning can occur at regular intervals based on a timer or can be dependent upon baghouse differential pressure. As differential pressure reaches a high limit, cleaning is started and continues until the differential pressure is returned to a low limit. A thin dust cake remains on the bag for further, more efficient filtration. The clean air exits the baghouse via the clean air plenum.

For more information on what baghouse is right for your operation, contact us..